Beryllium Copper Springs for Supporting Industrial Electric Equipment

Beryllium copper alloys have a number of properties such as high conductivity, good strength, corrosion resistance, etc. The main advantage of beryllium copper is its ability to be formed in a soft state. Later, it can be age hardened to exhibit spring properties. The high-conductivity of beryllium copper makes it perfect for electrical applications requiring high strength, conductivity or operating in extreme temperatures. SMSC provides beryllium copper springs to suit your requirements. We also design custom beryllium copper springs to meet the needs of new or upgraded electrical equipment.

Features and Specifications

Our springs are initially cold drawn, and then toughened with the help of milling techniques before the spring fabrication process takes place. The following are features of our cold drawn beryllium copper springs:

| Chemical Composition | Cu 98% Be 2% |

| Size Range | 0.003ʺ to 0.375ʺ |

| Elasticity | 18,000,000 |

| Maximum Temperature | 400°F |

| Standard | ASTM B197 |

| Gravitational Constant | 7,000,000 |

| Density g/cm3 | 8.260 |

| Density lb/in3 | 0.298 |

| Conductivity | 21 |

| Rockwell Hardness | C39 |

Properties of Beryllium Copper

Beryllium Copper is the best choice for manufacturing springs owing to its following properties:

- The alloy is highly machinable

- It is ductile

- It is weldable

- Beryllium Copper is resistant to non-oxidizing acids

- It has a good durability

SMSC Beryllium Copper Spring Offerings

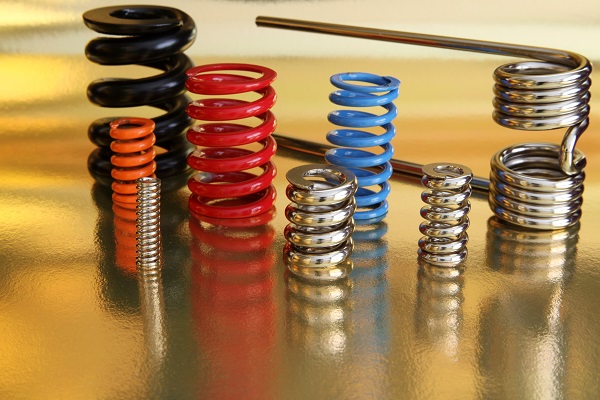

At SMSC, we design and manufacture three types of springs made from beryllium copper:

- Coil Springs: We offer beryllium copper coil springs for electrical applications that require a certain amount of tension, compression, or extension.

- Canted Coil Springs: Beryllium copper canted coil springs are used for protecting sensitive components from radio frequency interference (RFI) or electromagnetic interference (EMI).

- Leaf Springs: Our leaf springs can be used to support electrical components installed in hydraulic systems.

Industries Served

SMSC springs are designed to provide desirable benefits to users, while minimizing their costs. Being a well-known manufacturer of beryllium copper springs, we offer our products for electrical components to clients from different industries, including:

- Medical

- Hardware

- Aerospace

- Metalworking

- Oil and Energy

- Automotive

We keep the customer requirements at the forefront of operations. This helps us to serve our customers in a better way. For all your queries as well as design requirements related to Beryllium Copper springs, you can get in touch with us at smsc@windstream.net.

Upload Your CAD Drawing

Upload Your CAD Drawing