(Image Source – Wikipedia)

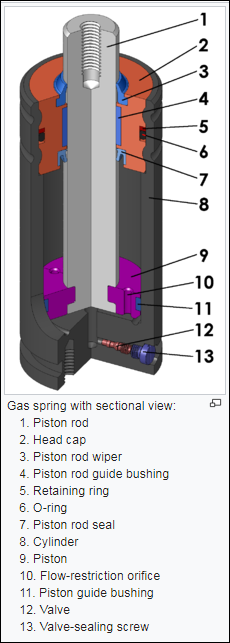

Gas springs feature a precision rod attached to a piston, which moves within a sealed high-pressure nitrogen-filled cylinder. The output force of the gas spring the difference between the pressure inside the cylinder and the atmospheric pressure acting outside of the rod. The internal pressure of the cylinder increases in response to gas displacement by the rod. This happens only when the piston rod enters into the cylinder, and it is called compression stroke. There are different types of gas springs used depending on their applications. This post will discuss the various types of gas springs and their applications.What are the Different Types of Gas Springs?

As said earlier, there are different types of gas springs. The following are a few:

-

- Standard Gas Springs: Standard gas springs feature a rod that is attached to a piston within a sealed cylinder. High-pressure nitrogen is filled inside the cylinder, which generates extended forces. These extended gas springs are reliable and compact, finding usage in many lifting and counterbalancing applications. Some applications of standard gas springs are listed below.

- Industrial & Agricultural Equipment

- Adjustable Chairs

- Photo Copier Covers

- Specialty and Recreation Vehicles

- Lids & Access Panel Covers

- Travel and Cargo Trailers

- Automotive Hood Props

- Standard Gas Springs: Standard gas springs feature a rod that is attached to a piston within a sealed cylinder. High-pressure nitrogen is filled inside the cylinder, which generates extended forces. These extended gas springs are reliable and compact, finding usage in many lifting and counterbalancing applications. Some applications of standard gas springs are listed below.

-

- Adjustable Locking Gas Springs: Adjustable locking gas springs allow the piston rod to be locked at any position in its stroke. The process is initiated by triggering a plunger that is linked to the piston rod. Upon pressing the plunger, the rod starts working as a compression gas spring. The rod gets locked in a position, when the plunger is released at any point in the stroke. Locking gas springs consist of components, such as piston rod, piston valve, cylinder, guide, seals, etc. Here are a few applications of adjustable locking gas springs:

- Hospital Beds

- Hospital Furniture

- Passenger Seats

- Emergency Casualty Trolleys

- Adjustable Locking Gas Springs: Adjustable locking gas springs allow the piston rod to be locked at any position in its stroke. The process is initiated by triggering a plunger that is linked to the piston rod. Upon pressing the plunger, the rod starts working as a compression gas spring. The rod gets locked in a position, when the plunger is released at any point in the stroke. Locking gas springs consist of components, such as piston rod, piston valve, cylinder, guide, seals, etc. Here are a few applications of adjustable locking gas springs:

-

- Custom Gas Springs: Custom gas springs are application specific gas springs, which are designed to work in various industrial applications. These applications include UAV launchers, MRI machines, UAV launchers, etc. Custom gas springs are available in EPDM, polyurethane, Viton and other special materials.

-

- Safety Locking Shroud Gas Spring: Safety locking gas springs come with an additional shroud mechanism around the rod. This mechanism lock the gas spring, when it is fully extended. Here are some industrial applications of safety locking shroud gas springs:

- Lift assist applications

- LCD display support

- Automotive applications

- Medical equipment

- Safety Locking Shroud Gas Spring: Safety locking gas springs come with an additional shroud mechanism around the rod. This mechanism lock the gas spring, when it is fully extended. Here are some industrial applications of safety locking shroud gas springs:

-

- Tension & Traction Gas Springs: Traction & traction gas springs help provide tension on the belt drive and mechanical assemblies by applying some force or maintaining tension. The operation of these springs is exactly opposite to that of compression gas springs. The springs are available in varied sizes and stroke ranges, which help determine its force range and K factor. These springs are generally made from stainless steel. The traction gas springs provide controlled pulling and adjusting as per the requirement. These springs are used in the following applications:

- Aerospace applications

- Oil dampeners

- Pick-up truck tailgates

- Furniture and cabinets

- Tension & Traction Gas Springs: Traction & traction gas springs help provide tension on the belt drive and mechanical assemblies by applying some force or maintaining tension. The operation of these springs is exactly opposite to that of compression gas springs. The springs are available in varied sizes and stroke ranges, which help determine its force range and K factor. These springs are generally made from stainless steel. The traction gas springs provide controlled pulling and adjusting as per the requirement. These springs are used in the following applications:

-

- Stainless Steel Gas Struts & Springs: Stainless steel gas struts and springs work best in corrosive environments. These gas springs have variants, such as micro compression, locking, and tension springs. All types of stainless steel gas springs, except micro gas springs feature a release valve. This helps the installer to release gas upon obtaining the correct force. Following are some applications where stainless steel gas springs are regularly used:

- Food and pharmaceutical applications

- Marine based applications

- Stainless Steel Gas Struts & Springs: Stainless steel gas struts and springs work best in corrosive environments. These gas springs have variants, such as micro compression, locking, and tension springs. All types of stainless steel gas springs, except micro gas springs feature a release valve. This helps the installer to release gas upon obtaining the correct force. Following are some applications where stainless steel gas springs are regularly used:

-

- Gas Spring Dampers: Gas spring dampers help in regulating the speed and motion using hydraulic oil. Gas dampers are basically used in lids, cover, and doors of devices that moves in a specific direction. They have a load capacity from 10-150 lbs., and various speed characteristics to meet the application needs. Some applications of gas spring dampers are as mentioned below:

- Motor vehicles

- Superstructures

- Agricultural vehicles

- Gas Spring Dampers: Gas spring dampers help in regulating the speed and motion using hydraulic oil. Gas dampers are basically used in lids, cover, and doors of devices that moves in a specific direction. They have a load capacity from 10-150 lbs., and various speed characteristics to meet the application needs. Some applications of gas spring dampers are as mentioned below:

Gas springs are manufactured in varied sizes and specifications, as per the customer’s requirement. As discussed these springs are designed to specific requirement and can operate for years without any flaw, if installed properly.